Сотобрус® «ОСНОВАТЕЛЬ»® – универсальное основание для теплицы или парника

Категория: основание для теплиц

Ценовой сегмент: средний

Начало серийного производства: 2025 год

Форма: сотовый поликарбонатный брус с уступом

Размеры бруса: 64х43 мм

Длина бруса: 2 м; 3 м; 4 м; 6 м; 8 м; до 13,5 м (под заказ)

Гарантия: 10 лет

Основание под теплицу своими руками

Сотовый поликарбонатный брус ОСНОВАТЕЛЬ® (Рис. 1) – надежное основание для парников и теплиц, которое устанавливается на грунт без фундамента. Это простая и легкая подставка под теплицу, являющаяся более выгодной альтернативой по отношению к таким материалам, как деревянный брус или металлический фундамент для теплицы. Сотовый брус из поликарбоната в 1,5-2 раза дешевле стального фундамента и в 10-15 раз легче деревянного бруса, традиционно используемого как постамент под теплицу. Сотобрус® ОСНОВАТЕЛЬ® может применяться в качестве основания для теплиц из поликарбоната, пленки или нетканого укрывного материала типа «Спанбонд».

Сотовый поликарбонатный брус по всей длине имеет специальный ступенчатый вырез под металлическую профильную трубу 20х20/30/40, являющуюся основой для изготовления большинства каркасов теплиц. В том числе для теплиц с усиленной двойной дугой каркаса, где нижняя горизонтальная перемычка расположена на высоте не менее 25 мм от основания конструкции. Благодаря специально разработанной форме Сотобруса®, его отдельные участки легко соединяются между собой с помощью небольших кусков металлической профильной трубы 20х20 без дополнительных крепежных элементов.

За счет продольного ступенчатого выреза по всей длине поликарбонатного бруса обеспечивается двухсторонний, более плотный контакт металлического каркаса с пластиковым основанием теплицы и его более герметичное прилегание, в результате чего повышается стабильность всей конструкции, снижаются теплопотери, создается дополнительный защитный барьер от проникновения насекомых. Благодаря своей пустотелой ячеистой структуре, Сотобрус® ОСНОВАТЕЛЬ® хорошо изолирует металлический каркас от контакта с землей, создавая эффективный гидро- и теплоизоляционный контур для основы теплицы по периметру.

Покупая поликарбонатный брус ОСНОВАТЕЛЬ®, вы приобретаете не только универсальное основание для теплицы или парника без необходимости создания дорогостоящего фундамента, но и возможность легкой самостоятельной установки теплицы на брус своими руками. Это сэкономит ваши деньги, ускорит процесс монтажа и в целом повысит эффективность любого огорода под крышей.

Как установить теплицу из поликарбоната на грунт без фундамента

Поликарбонатный брус ОСНОВАТЕЛЬ® (Рис. 2) является универсальным основанием (подставкой), предназначенной для установки теплицы на грунт без фундамента. В зависимости от вида покрытия вашей теплицы (поликарбонат, пленка или спанбонд), толщины используемого материала, а также показателей снеговой нагрузки в регионе, перед началом монтажа необходимо выбрать способ установки бруса – вертикальный или горизонтальный.

Преимущества поликарбонатного бруса ОСНОВАТЕЛЬ® :

- Универсальный. Универсальное основание под теплицу или парник;

- Простой. Простая установка теплицы на грунт без фундамента;

- Удобный. Не требует дополнительных крепежных элементов;

- Энергосберегающий. До 20% снижает теплопотери в теплице;

- Выгодный. Дешевле металлического фундамента в 1,5-2 раза;

- Легкий. Легче деревянного бруса в 10-15 раз;

- Практичный. Не нужна обработка, пропитка или покраска;

- Эффективный. Защитный барьер от проникновения насекомых.

Технические характеристики поликарбонатного бруса «ОСНОВАТЕЛЬ»®

| Основные параметры | Специальный брус под теплицу из поликарбоната | ||||

|---|---|---|---|---|---|

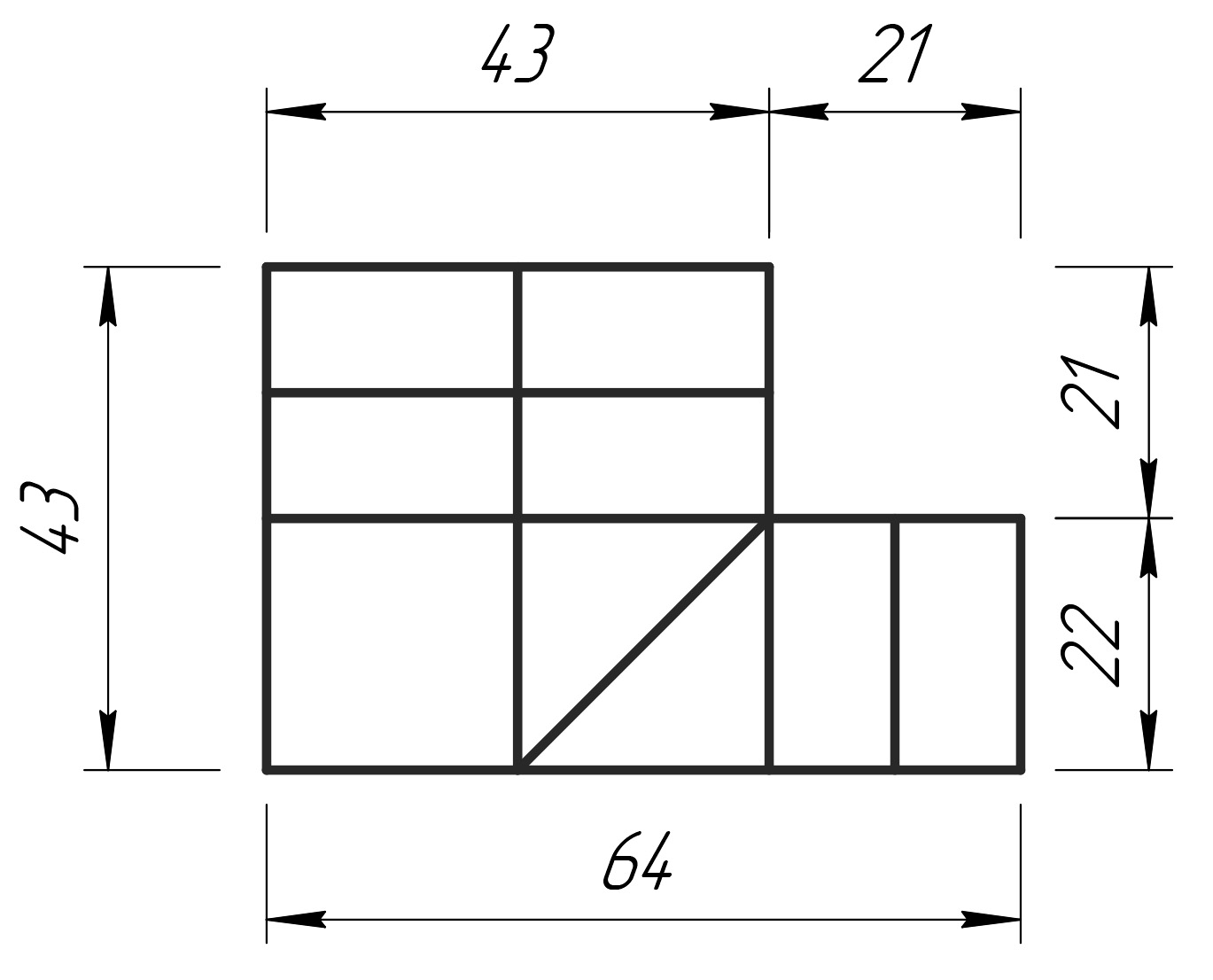

| Ширина, мм | 64 | ||||

| Высота, мм | 43 | ||||

| Длина, м | 2; 3; 4; 6; 8 (до 13 «под заказ») | ||||

| Срок службы, лет | 10 | ||||

| Несущая способность при вертикальном способе монтажа, кг/м.п | до 450 | ||||

| Несущая способность при горизонтальном способе монтажа, кг/м.п | до 1000 | ||||

| Поперечное сечение |

|

||||

| Ударная прочность, кДж/м² | 60 | ||||

| Твёрдость по Роквелу, HR (M) | 75 | ||||

| Температура эксплуатации, ºC | от -50 до +120 | ||||

| Температура деформации, ºC | 130 | ||||

| Тепловое расширение, мм/м | ≤ 4,0 | ||||

| Теплопроводность, Вт/(м*К) | 0,09-0,1 | ||||

| Водопоглощение, % | 0,4 | ||||

Способы установки и применение Сотобруса® ОСНОВАТЕЛЬ® :

- Вертикальный способ установки Сотобруса® ОСНОВАТЕЛЬ® (Рис. 3) идеально подходит для сезонных парников и теплиц из пленки, спанбонда или сотового поликарбоната толщиной 4-6 мм, устанавливаемых на грунт без фундамента и имеющих ограниченное пространство внутри теплицы. При вертикальном способе монтажа несущая способность Сотобруса® составляет 450 кг/м.п.* Это в несколько раз превышает необходимый запас прочности основания для любого парника или стандартной теплицы из поликарбоната 60-140 кг/м.п, рассчитанный как вес металлического каркаса + вес сотового поликарбоната + величина снеговой нагрузки для I-IV снеговых районов России. Дополнительным преимуществом является то, что при вертикальной установке поликарбонатного бруса образуется больше полезного пространства внутри теплицы.

- Горизонтально установленный Сотобрус® ОСНОВАТЕЛЬ® (Рис. 4) – это отличная основа для теплицы из сотового поликарбоната толщиной 8-10 мм или специального монолитного поликарбоната «ПЛАСТИЛЮКС ДЛЯ ТЕПЛИЦ» толщиной 0,8 мм.

Горизонтальный способ установки поликарбонатного бруса подходит для всех стандартных теплиц: 2х3, 2х4, 2х6, 2х8, 3х4, 3х6, 3х8, 4х6, 4х8 метров, а также для теплиц с усиленной двойной дугой каркаса или большим количеством подвязок для овощей и внутренних аксессуаров. При горизонтальном способе монтажа Сотобруса® его характеристики значительно возрастают и более чем в 6 раз увеличивается несущая способность сборного пластикового фундамента для теплицы (до 1000 кг/м.п)*.

Сотобрус® ОСНОВАТЕЛЬ® в горизонтальном положении может также служить как простой и недорогой фундамент для беседки, который можно сделать своими руками. Это легко получится, если основание беседки выполнено из металлической профильной трубы 20х20 или эта труба приварена (прикручена) к нижней части беседки по периметру.

Видео презентация основания для теплицы и парника Сотобрус® «ОСНОВАТЕЛЬ»®

Правила хранения, транспортировки и установки поликарбонатного бруса для теплицы

До момента начала использования поликарбонатного бруса ОСНОВАТЕЛЬ® в качестве подставки под теплицу, его хранение и транспортировка должны осуществляться исключительно в горизонтальном положении. Нельзя хранить сотовый поликарбонатный брус под прямыми солнечными лучами или без накрытия от дождя (Рис. 5)!

Как сделать основание под теплицу из поликарбонатного бруса ОСНОВАТЕЛЬ®

Чтобы правильно сделать основание под теплицу из поликарбоната, пленки или спанбонда с применением Сотобруса® ОСНОВАТЕЛЬ®, необходимо выполнить следующие действия:

1. Убедиться в том, что каркас вашей теплицы изготовлен из металлической профильной трубы 20х20, 20х30 или 20х40 (ШхВ), а его нижняя часть не содержит выступающих элементов в местах будущего соединения с поликарбонатным брусом. При наличии болтов с выступающей шестигранной головкой в основании каркаса теплицы, их необходимо заменить на болты с круглой потайной головкой (Рис. 6).

2. Подготовить на грунте ровную площадку на возвышенной части участка для предотвращения подтапливания урожая.

3. Собрать металлический каркас теплицы согласно инструкции по монтажу от производителя, с учетом требований, указанных в пункте 1 настоящих Правил. Прочно зафиксировать все места соединения каркаса для обеспечения жёсткости конструкции при установке теплицы на брус.

4. Произвести замеры нижней части металлического каркаса, который будет устанавливаться на основу для теплицы по периметру.

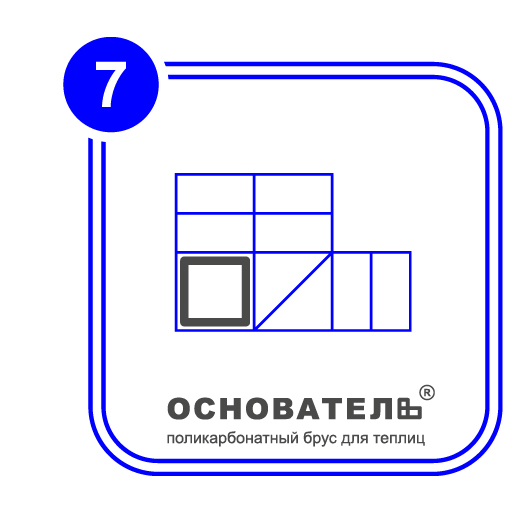

5. Приготовить четыре сотовых поликарбонатных бруса под размеры основания теплицы. Например, для изготовления основания под теплицу из поликарбоната 3х6 нужны два профиля длиной 3 м и два профиля длиной 6 м. Если ваша теплица большего размера, используйте для соединения двух профилей небольшой обрезок металлической профильной трубы 20х20. Он вставляется в специальную квадратную ячейку поликарбонатного бруса ОСНОВАТЕЛЬ® (Рис. 7) и не требует дополнительных крепежных элементов. Таким образом, соединив между собой несколько профилей Сотобруса®, вы можете самостоятельно сделать любую ширину и длину основания для теплицы своими руками.

6. Выполнить порезку и подгонку угловых участков Сотобруса® ОСНОВАТЕЛЬ® под углом 45 градусов таким образом, чтобы продольный ступенчатый вырез, предназначенный для установки каркаса теплицы, всегда оставался с верхней наружной стороны профиля (Рис. 8). Для резки сотового поликарбонатного бруса рекомендуется использовать циркулярную пилу с упором, снабжённую мелкими неразведёнными зубьями, армированными твёрдыми сплавами. Лучше всего подходят пилы со скоростью не менее 3200 об/мин. При этом сам поликарбонатный профиль необходимо прочно зафиксировать для предотвращения вибрации.

Для обеспечения плотного соединения углов и предотвращения попадания земли внутрь сборного пластикового фундамента для теплицы рекомендуется для выполнения точной порезки использовать угломер 45 градусов. После завершения процедуры резки удалите остатки пыли и мелкой стружки с обрезанных краёв профиля сжатым воздухом или пылесосом.

7. Выкопать в земле канавку шириной 15 см и глубиной 2 или 4 см, в зависимости от способа установки поликарбонатного бруса под теплицу. Для вертикального расположения профиля в земле необходимо сделать углубление 4 см, для горизонтального – 2 см.

Состыковать все углы Сотобруса® между собой и зафиксировать их снаружи с помощью обычного скотча или малярной ленты (Рис. 9). Этого достаточно для того, чтобы легко и быстро установить сборный пластиковый фундамент для теплицы на грунт. Надежность угловых соединений поликарбонатного бруса обеспечивается за счет жесткости устанавливаемого металлического каркаса и его крепления к пластиковому основанию теплицы. Дополнительные крепежные элементы для соединения бруса в углах не нужны.

Для тех, кто привык использовать традиционные способы соединения углов, можно взять крепежные оцинкованные уголки 80х80х60х1,5 мм (для вертикально расположенного бруса) и 80х80х40х1,5 мм (для горизонтально расположенного бруса) и установить их таким образом, чтобы нижняя часть каждого уголка совпадала с нижней частью Сотобруса® (Рис. 10). При правильной установке оцинкованных монтажных уголков должно получиться четыре угловых ложе 90о для размещения металлического каркаса теплицы.

Крепление оцинкованных монтажных уголков к пластиковому основанию теплицы необходимо производить с наружной части поликарбонатного бруса ОСНОВАТЕЛЬ® с помощью саморезов для гипсокартона по металлу 3,5х30 мм с частой (мелкой) резьбой. Это можно сделать как вручную, так и с помощью шуруповерта, предварительно установив его на минимальную скорость с самым маленьким моментом затяжки, не допуская прокручивания саморезов внутри пластикового основания.

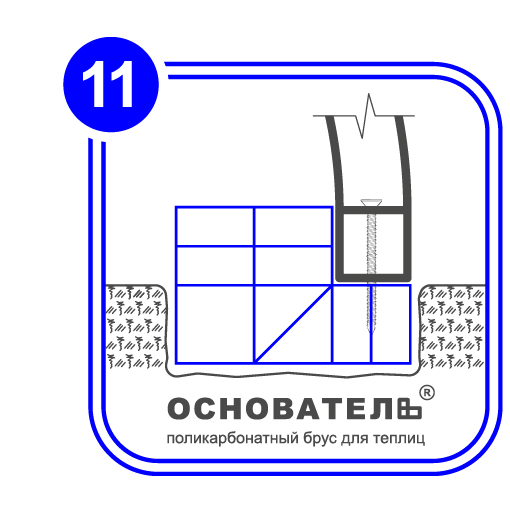

8. Поместить в углубление на грунте собранную подставку под теплицу из поликарбоната, обеспечив её правильное позиционирование и устойчивость. При этом нижняя часть ступенчатого выреза каждого поликарбонатного бруса, входящего в состав сборного пластикового фундамента под теплицу, должна оставаться на уровне с землей (Рис. 11). Затем установить металлический каркас на ступенчатый вырез Сотобруса® и далее воспользоваться одним из двух способов крепления теплицы к брусу.

Крепление каркаса теплицы к Сотобрусу® ОСНОВАТЕЛЬ® с помощью саморезов:

Выполнить крепление каркаса теплицы к Сотобрусу® ОСНОВАТЕЛЬ® с помощью саморезов по металлу с частой (мелкой) резьбой 3,5х35 мм (для горизонтально расположенного бруса) и 3,5х50 мм (для вертикально расположенного бруса) через каждые 50-60 см основания теплицы. Если для соединения углов пластиковой рамы были использованы оцинкованные крепежные уголки с отверстиями, то металлический каркас теплицы также необходимо прикрепить к этим монтажным уголкам при помощи саморезов со сверлом по металлу с прессшайбой 4,2х15 мм.

Крепление каркаса теплицы к Сотобрусу® производится сквозь металлическую профильную трубу (Рис. 11) через предварительно просверленные вертикальные отверстия в металле диаметром 4 мм. Если изготовитель каркаса предусмотрел собственные крепежные отверстия для соединения с фундаментом, используйте их. Глубина вкручивания саморезов в сотовый поликарбонатный брус ОСНОВАТЕЛЬ® должна составлять 10-15 мм (при горизонтальной установке профиля) и 25-30 мм (при вертикальной установке профиля). Это обеспечивает надёжное и долговечное соединение всех элементов пластикового фундамента для теплицы.

Крепление каркаса теплицы к Сотобрусу® ОСНОВАТЕЛЬ® с помощью стяжек:

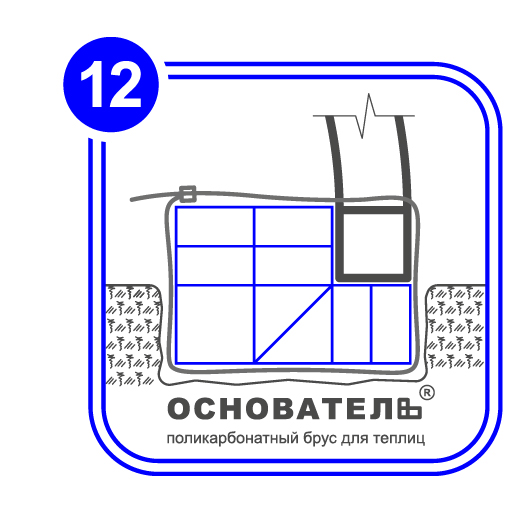

Второй способ крепления теплицы к брусу – это более быстрое и более удобное соединение металлического каркаса с поликарбонатной рамой при помощи монтажных пластиковых стяжек через каждые 30-50 см по периметру основания теплицы (Рис. 12). Для надежного крепления теплицы к брусу рекомендуется использовать морозостойкие нейлоновые стяжки (хомуты) черного цвета с УФ-стабилизацией длиной 250 мм и шириной ленты от 3,6 до 4 мм. Для этого подходят пластиковые стяжки следующих размеров: 3,6х250 мм; 3,8х250 мм; 4х250 мм. Чем тоньше монтажные стяжки, тем большее их количество необходимо использовать на один погонный метр основы для теплицы по периметру. Как правило, на каждый метр сотового поликарбонатного бруса используется от 3-х до 5-ти стяжек (4х250 мм - 3 шт./м; 3,8х250 мм - 4 шт./м; 3,6х250 мм - 5 шт./м).

Если после установки теплицы на брус и его крепления любым из вышеуказанных способов остаются щели между металлическим каркасом и пластиковым основанием теплицы, например из-за неровностей металла, выступающих болтов или неточности порезки поликарбонатного бруса, их можно заделать обычным силиконовым герметиком или поролоновым уплотнителем для окон. Запрещается использование любых акриловых замазок или акрилосодержащих герметиков!

9. Выкопать углубления с наружной стороны основания теплицы глубиной 45-50 см в местах установки грунтозацепов (якорей), из расчета по одному грунтозацепу на каждые 2 метра поликарбонатного бруса, плюс по одному – на каждый угол теплицы. Грунтозацепы крепятся к наружной боковой стенке металлического каркаса теплицы (Рис. 13) при помощи саморезов со сверлом по металлу с прессшайбой 4,2х15 мм. Сотобрус® ОСНОВАТЕЛЬ® в комбинации с грунтозацепами длиной 45-50 см обеспечивает хорошую устойчивость каркаса при установке теплицы на грунт без фундамента.

10. Монтаж финишного прозрачного покрытия из пленки, поликарбоната или спанбонда следует выполнять только после полного завершения установки и закрепления металлического каркаса на пластиковом основании теплицы, а также фиксации всех якорей.

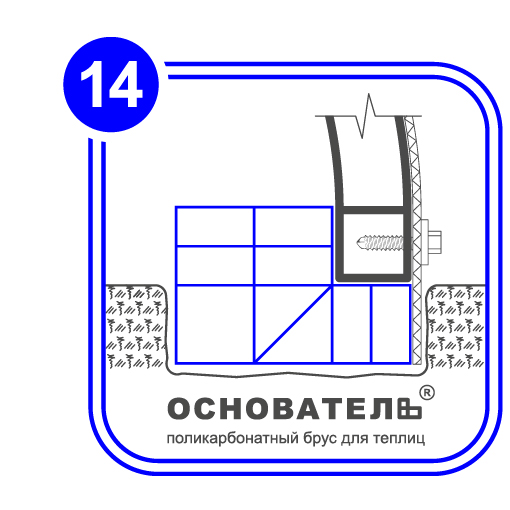

Если длины укрывного материала хватает, то для минимизации теплопотерь и поддержания оптимальной влажности в теплице до необходимого уровня 60-70% рекомендуется нижний край светопрозрачного покрытия довести до нижнего края поликарбонатного бруса и прикрепить к горизонтальной стальной трубе каркаса теплицы через каждые 30-50 см с помощью саморезов 4,2х15 со сверлом по металлу и пресс-шайбой с резиновой прокладкой (Рис. 14). Такой способ установки финишного покрытия обеспечивает недопущение образования мостиков холода, по которым происходит утечка тепла, а также предотвращает возникновение сквозняков и лучше защищает внутреннее пространство теплицы от проникновения вредителей из грунта.

Минимальная нижняя граница для сотового или монолитного поликарбоната при использовании его в качестве прозрачного покрытия – это нижний край металлического каркаса теплицы, установленный на поликарбонатный брус (Рис. 15). Вне зависимости от выбранного вида укрывного материала, он должен полностью перекрывать металлическое основание теплицы для предотвращения образования мостиков холода, а в идеале – доходить до нижнего края Сотобруса® или даже заводиться под него, если в качестве покрытия используется пленка или спанбонд.

При использовании сотового поликарбоната в качестве укрывного материала для теплицы, необходимо предварительно запечатать его открытые торцы специальной перфорированной лентой шириной 25 мм – для возможности отвода конденсата в грунт и недопущения проникновения насекомых во внутренние полости листов.

Дальнейшее крепление финишного покрытия необходимо выполнять согласно инструкции по монтажу для вашего материала. После окончательной установки и закрепления светопрозрачного покрытия на каркасе теплицы свободное место с обеих сторон поликарбонатного бруса необходимо засыпать землей и утрамбовать. Запрещается использовать песок для этих целей!

Инновационная конструкция Сотобруса® ОСНОВАТЕЛЬ®, имеющая продольный угловой вырез в форме ступеньки, в 2 раза лучше защищает внутреннее пространство парников и теплиц от проникновения насекомых, на 15-20% снижает теплопотери, а также помогает повысить влажность в теплице до необходимого уровня 60-70%.

Размеры поликарбонатного Сотобруса® под теплицу

Габаритные размеры Сотобруса® под теплицу из поликарбоната (размер поперечного сечения сотового поликарбонатного бруса ОСНОВАТЕЛЬ®) – 43 х 64 мм. При вертикальном расположении профиля его ширина равняется 43 мм, высота 64 мм (Рис. 16). При горизонтальном расположении профиля ширина составляет 64 мм, а высота, соответственно, 43 мм (Рис. 17). Размер продольного углового выреза (уступа), предназначенного для установки каркаса теплицы, всегда остается неизменным 21 х 21 мм.

Сотовый поликарбонатный брус изготавливается длиной 2 м, 3 м, 4 м, 6 м и 8 метров. Это стандартные размеры бруса под теплицу, которые производятся заводом «ПЛАСТИЛЮКС-ГРУПП» и всегда есть в наличии на региональных складах предприятия. Сотовый профиль длиной 2 м, 3 м и 4 м используется в качестве основания для парников и теплиц размером 2х3, 2х4, 3х4 метра. Профиль 3 м и 6 м выпускается как брус под теплицу из поликарбоната 3х6. Профиль 3 м и 8 м – это готовая основа для теплицы по периметру 3 на 8 метров.

Поликарбонатный брус ОСНОВАТЕЛЬ® оптом от производителя

Постоянные клиенты завода-производителя поликарбонатного бруса для теплиц ООО «ПЛАСТИЛЮКС-ГРУПП» говорят, что Сотобрус® ОСНОВАТЕЛЬ® – это самый удобный и простой фундамент для теплицы, с которым им приходилось работать. Поскольку он универсальный, имеет различные способы установки, легко собирается, быстро монтируется и не нуждается в дополнительных крепежных элементах.

Для дилеров и оптовых покупателей действуют специальные условия, в том числе возможность изготовления продукции по размеру заказчика, с длиной профиля от 1,5 метра до 13,5 метров (длина полуприцепа еврофуры). Продажа поликарбонатного бруса оптом от производителя осуществляется кратно упаковкам. В одной упаковке находится 6 профилей Сотобруса®. Размеры упаковки 130х110 мм. Цвет профиля – черный.

Поликарбонатный брус ОСНОВАТЕЛЬ®, используемый для изготовления сборного пластикового фундамента для теплицы, является инновационным техническим решением, зарегистрированным в качестве изобретения. Лицензиатом и единственным производителем поликарбонатного бруса для теплиц, имеющим исключительное (монопольное) право на использование изобретения «Сборный фундамент для теплиц», является ООО «ПЛАСТИЛЮКС-ГРУПП», компания по изготовлению сотового поликарбоната и поликарбонатных профилей, г. Белгород. Официальный сайт polikarbonates.com.

Купить Сотобрус® оптом или стать дилером по продаже универсального поликарбонатного бруса для теплиц можно обратившись в отдел оптовых продаж либо к ближайшему региональному менеджеру предприятия. Приглашаем к сотрудничеству производителей парников и теплиц из поликарбоната.

Внимание!

Торговые обозначения СОТОБРУС® и ОСНОВАТЕЛЬ® являются товарными знаками, обладающими правовой защитой. Исключительное право на использование указанных товарных знаков, а также право на использование изобретения «Сборный фундамент для теплиц» принадлежит ООО «ПЛАСТИЛЮКС-ГРУПП». Любое незаконное использование товарного знака, а также незаконное копирование, изготовление и/или распространение запатентованной продукции без разрешения патентообладателя является правонарушением, влекущим за собой финансовую или уголовную ответственность.

За информацию о незаконном использовании объектов интеллектуальной собственности ООО «ПЛАСТИЛЮКС-ГРУПП» предусмотрено вознаграждение.

* Несущая способность сотового поликарбонатного бруса ОСНОВАТЕЛЬ® – это фактическое значение, полученное в результате испытаний, производимых на заводе «ПЛАСТИЛЮКС-ГРУПП» на специальном тестировочном оборудовании при температуре окружающей среды 20 градусов Цельсия.